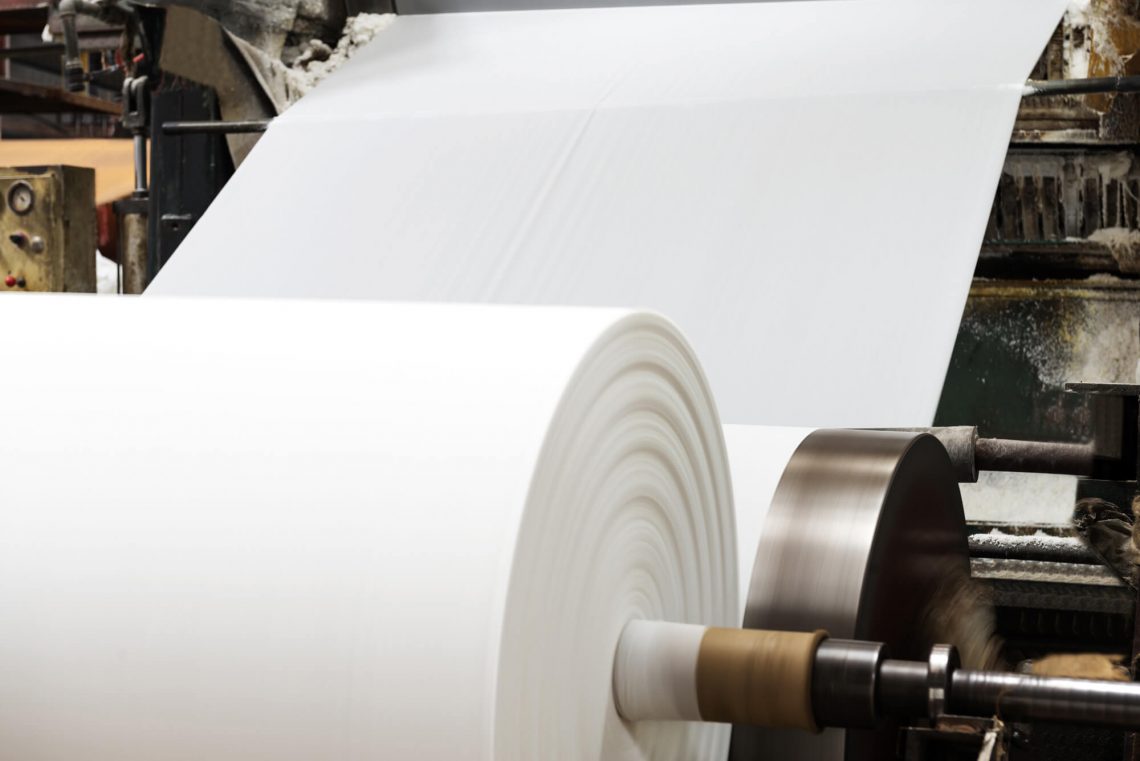

Thermal spray and wear resistance for paper mills

In the pulp and paper sector, there are problems related to abrasive dust and friction from the paper (fibers) directly on the equipment. The use of highly corrosive liquids in the process also generates components decay. In both cases, Metallitech offers thermal spray solution, such as HVOF, HVAF and Plasma coating, which substantially enhance wear life of the equipment.

Thermal spray application

We will use our thermal spray expertise, using HVOF, HVAF and plasma spray, on a variety of equipment such as:

- Auger screw

- Pumps

- Valves

- Pistons

- Drive shaft

- Sleeves

- Anticorrosion coatings

- Traction rolls

- Bearing seat repair and/or value-added

- Sealing seat repair and/or value-added