Flame spray

Among the thermal spray techniques, Flame spray is the most versatile and least expensive. This technology is capable to spray a wide variety of chemical compositions, providing that it is applied using wire or powder.

The process uses chemical reaction between oxygen and a fuel gas (acetylene, hydrogen) to produce a source of heat. This thermal source creates the flame.

When using wire as a feeding material, the flame is used to melt the material and project it with compressed air.

Flame spray process using powder as a feed material is simpler: powder particles are projected through the torch, generating a plastic stage, then it is projected on the substrate using compressed air.

Because of the limited amount of heat produced by its gun, this thermal spray coating process is however limited to low melting point elements or alloys.

Flame spray process using powder as a feed material is simpler: powder particles are projected through the torch, generating a plastic stage, then it is projected on the substrate using compressed air.

Because of the limited amount of heat produced by its gun, this thermal spray coating process is however limited to low melting point elements or alloys.

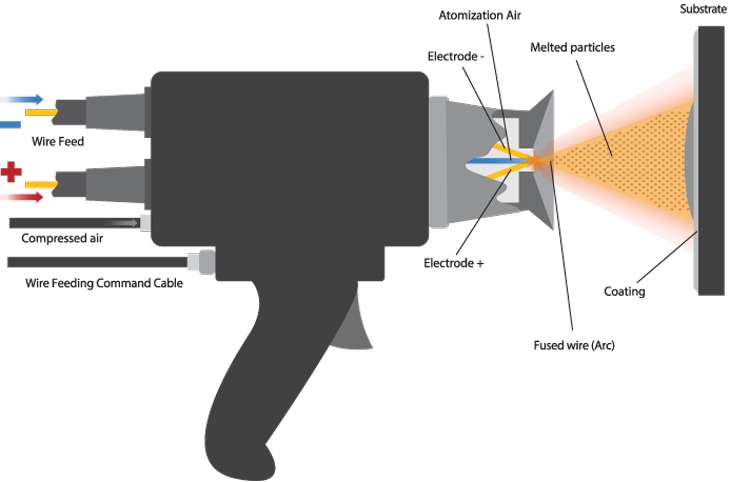

Wire arc spray

This process uses an electric arc between two metallic wires acting as electrodes. A compressed air jet located in the axial point of the arc pulverizes the molten metal on the substrate.

One of the features of the wire ARC spray process is that two different types of metallic wires can be used simultaneously to produce a new specific alloy for a particular application.

Because of a higher velocity of the projected particles, this type of industrial coating generates a denser coating and offers a better adherence than the coating obtained by flame spray.

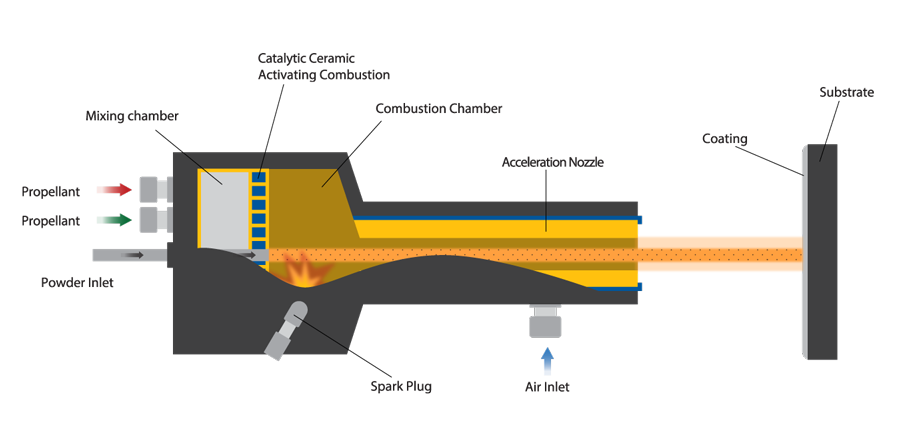

High Velocity Oxy-Fuel spray (HVOF spray)

HVOF spray process is a supersonic flame spray process, in which enough energy is generated to turn powder particles into a semi-molten stage. The velocity of the feeding material is obtained through the fuel combustion a gas (propane, propylene, hydrogen, acetylene, natural gas) or liquid (kerosene) and oxygen. The burned gas in the combustion chambers are accelerated to reach a velocity higher than the speed of sound (Mach 3), at the nozzle outlet. The temperatures and accelerations reached by the flame enable a coating density higher than any other process.

HVOF offers an excellent bonding on the substrate, along with a low level of coating porosity. The relatively low temperature (3000C) offers certain features for some materials; for example, less decarburizing for carbide powders and less oxidation for metallic powders. This enables excellent mechanical properties for the coating: high density, great bonding, very good corrosion and wear resistance.

High Velocity Air Fuel spray (HVAF spray)

This high speed air-fuel process called HVAF is a thermal spray process used to coat high performance cemented carbides and metallic powders. This technology is used to protect parts against erosive and corrosive wear.

This is a hot pulverizing process, colder than HVOF but hotter than cold spray. The HVAF gun uses axial powder injection through an air-fuel combination jet at 1900-2500C. it works with a combustion gas and compressed air (supplied by a 400 CFM at 125psi air compressor). This process can apply efficiently carbide based materials. Tungsten carbide is the dominating material applied by HVAF, for wear and abrasive resistance purposes.

HVAF prevents overheating of powder material which can be seen in the hot jets of conventional thermal spraying techniques (such as Plasma or HVOF). Thereby, particles are mainly solid when they hit the substrate, slowing down oxygen diffusion. This process enables metal application with almost no oxidation, as in cold spray. All common powder projection materials can be applied with HVAF except for ceramics.

HVAF can apply metals, carbides and other alloys of metallic powders at a thickness between 5 and 53 microns. Deposition efficiency is between 50% to 75% for carbide powders, and from 60% to 85% for metallic powders.

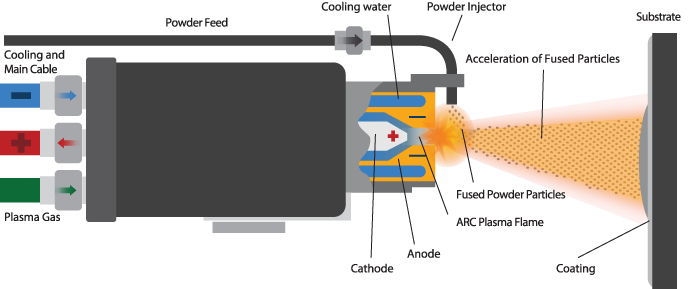

Plasma spray

The Plasma spray process uses water cooled anode and cathode, where a high frequency electric arc is generated and maintained by a low voltage electric source.

Dissolved molecular gases (argon nitrogen and hydrogen or helium) are ionized and generate an electric arc. Gases are carried out through the anode and expand. This dilation produce a blockage of the anode, forcing the gases to exit through the cathode.

Particles are accelerated and fused and then projected on the coating surface with a very large kinetic energy allowing an optimal bonding strength.

The plasma spray process is used for high melting point materials. It offers a very good coating quality.

Weld coating

Weld coating technique other than thermal spray that is used by Metallitech.

Welding is used to generate very thick deposits (several millimetres) and create an excellent bond.

We offer four types of welding processes:

- Shielded metal arc welding (Spray and fuse SMAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Flux-cored arc welding (FCAW)

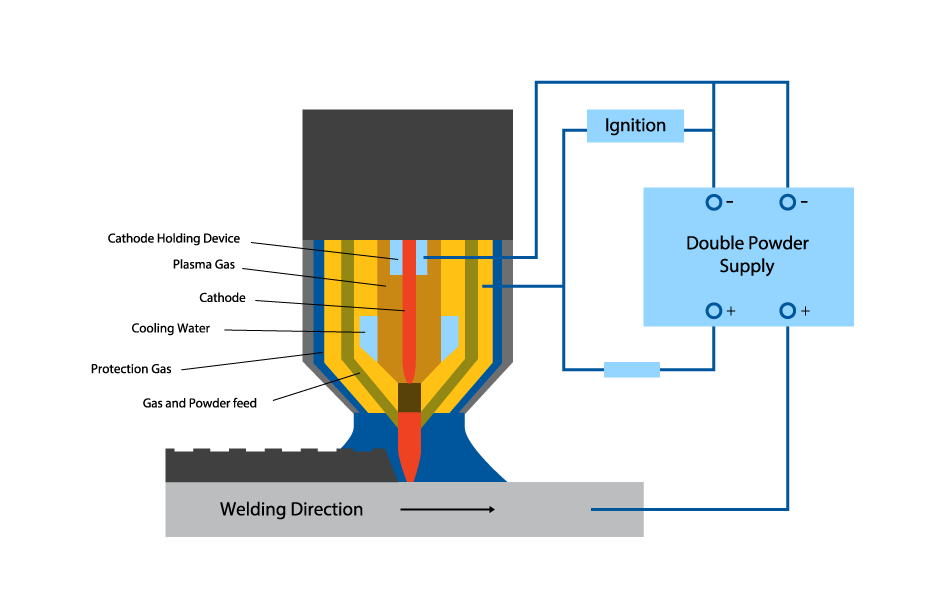

Plasma Transferred Arc Welding (PTAW)

PTA welding is used to melt a metallic coating on a substrate in order to increase wear and corrosion resistance.

Through the process, metal powder is introduced in a weld pool generated by the high temperature plasma arc (up to 5000C). The coating hardened by PTAW is a real welding process, offering a strong metallic bonding between the substrate and the deposit.

During the PTAW process, two continuously fed currents are used to create a non transferred arc (pilot arc), between the tungsten electrode (-) and the anodic nozzle (+). Then an electric arc is transferred between the tungsten electrode (-) and the work piece (+).

The pilot arc is switched on by a high frequency device. The plasma gas circulating around the cathode is ionized at the tip of the electrode.

When the transferred arc is switched on, the work piece becomes part of the electrical circuit and the plasma arc is focused through the torch outlet inside the work piece. Powder is injected though the plasma and is projected in the weld pool at low speed. One can dope some existing alloys to better suit the specific needs.

Deposit thickness ranges from 0.6 to 6.0mm and bead width ranges from 3 to 10mm during one pass. For multiple passes, deposit thickness can reach up to 20mm and width up to 30mm.

Control of dilution is one of the most distinguishing characteristics in the PTAW process. PTAW can be optimized with a dilution level as low as 5%, compared to 20-25% obtained by the other welding processes, such as MCAW and GTAW. Consequently, one can maintain the original properties of the deposit material even with only one pass.

COMPARISON OF DIFFERENT THERMAL SPRAY COATING TECHNIQUES AND COATING PROCESSES

| Characteristics | Powder Flame SPRAY | WIRE FLAME SPRAY | WIRE ARC SPRAY | H.V.O.F | H.V.A.F | Plasma Spray |

|---|---|---|---|---|---|---|

| Heat source | Flame | Flame | Electric arc | Flame | Flame | Plasma |

| Source temperature (deg.°C) | 3000 | 3000 | 6000 | 3000 | 2500 | 12000 |

| Particle Carrier | Gas Flame | Compresse d’air | Compresse d’air | Gas Flame | Gas Flame | Gas Flame |

| Particle speed (m/s) | 40 | 150 | 300 | 700 | 700 | 200 |

| Filler Material State | Powder | Wire | Cored Wire | Powder | Powder | Powder |

| Filler Material Category | Metals Cermets Ceramics | Metals Cermets Ceramics | Metals Cermets | Metals Cermets | Metals Cermets | Metals Cermets Ceramics |